Hydraulic Valves

Directional control valves are used to control the direction and movement of hydraulic fluid through a system. They are often referred to as switching valves and come in three main categories: hydraulic check valves, directional spool valves and poppet valves that make up the different types of control valves.

Our Brands

Check valves are the simplest form of hydraulic devices in that they permit free oil flow in one direction and block oil flow in the opposite direction. Check valves may also be used as a directional or pressure control in a hydraulic system.

Our Brands

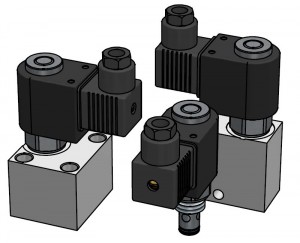

Poppet valves are used in hydraulic systems. They are commonly controlled through solenoids and can be set to be either normally-closed or normally-open in their de-energized states. They are also used as check valves to provide one-way flow and as relief valves to guard against over pressure.

Our Brands

Monoblock: Have many outstanding features including high performance, high efficiency, small volume, mass flow, and leak proof. In addition, the compact direction control valves have fixed and big pull rods to control direction, providing various ports and circuit valves.

Sectional: Offers multi-function control valve method to solve hydraulic circuit system requirement. The compact construction design is one of strong features for sectional directional control valves include other features, such as low pressure drop high efficiency.

Our Brands

A hydraulic solenoid valve is a solenoid-controlled directional valve used in a hydraulic system for opening & closing or changing the direction of flow of the liquid. The valve operates with a solenoid, which is an electric coil wound around a ferromagnetic core at its centre.

Our Brands

A hydraulic manual directional valve used in hydraulic system for opening & closing or changing the direction of flow of the liquid.

Our Brands

Pressure relief valves are used in hydraulic systems to limit the system pressure to a specific set level. If this set level is reached, the pressure relief valve responds and feeds the excess flow from the system back to the tank.

Note: the pressure relief valve is a normally closed pressure control valve

Our Brands

The purpose of pressure-reducing values is to keep the secondary pressures correct in branches of hydraulic systems. Most pressure-reducing valves are open and 2 way this allows the pressure to flow freely until they reach further downstream where there is a set pressure.

Sequence valves can be used to sense pressure (port 1) in one circuit and then open and supply oil to a secondary circuit (port 2) at a predetermined pressure. A typical application would be when maintained clamping pressure is required in the primary circuit while work is being performed in the secondary circuit.

Our Brands

Counterbalance valves are used in hydraulic systems working with an overriding (run-away) or suspended load. They are designed to create back pressure at the return line of the actuator to prevent losing control over the load.

Our Brands

Unloading valves are used in hydraulic circuits, these valves would stop or remove the flow of the pump back to the tank when the machine is not operating. So by this reduction of heat and energy saving can be achieved because the prime mover load is reduced.

Our Brands

The purpose of a flow control valve is to regulate the flow rate in a specific portion of a hydraulic circuit. In hydraulic systems, they’re used to control the flow rate to motors and cylinders, thereby regulating the speed of those components.

Our Brands

A needle valve is used to accurately control flow rates of clean fluids. The adjustments are gradual and smooth for controlling the flow rate.

Our Brands

Allow hydraulic oil into different paths from one or more sources. Will usually consist of a spool inside a cylinder which is mechanically or electrically actuated. The position of the spool restricts or permits flow, thus it controls the fluid flow.

Our Brands

Designed to control double pumps of a Hi-Low system. It unloads a low-pressure pump when system pressure rises above-set pressures and only high-pressure pump delivers the flow. Nominal flow and pressure ratings model max (Check Models).

Our Brands

Prefill valve is a drain valve which drains oil between the cylinder and tank. The prefill valve prevents the oil from flowing from the Hydraulic cylinder to the main tank while pressurizing inversely the hydraulic cylinder will make oil drain to the tank when reversion.

Our Brands

A pressure switch is an instrument that automatically senses a change in pressure and opens or closes an electrical switching element, when a predetermined pressure point is reached. A pressure-sensing element is that part of a pressure switch that moves due to the change in pressure.

Our Brands

A non-return valve allows a medium to flow in only one direction and is fitted to ensure that the medium flows through a pipe in the right direction, where pressure conditions may otherwise cause reversed flow.

Our Brands